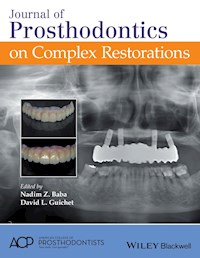

Journal of Prosthodontics on Complex Restorations ebook

0,0

339,99 zł

339,99 zł

-50%

Zbieraj punkty w Klubie Mola Książkowego i kupuj ebooki, audiobooki oraz książki papierowe do 50% taniej.

Dowiedz się więcej.

Dowiedz się więcej.

- Wydawca: John Wiley & Sons

- Kategoria: Biznes, rozwój, prawo

- Język: angielski

Journal of Prosthodontics on Complex Restorations compiles 34 of the journal's best articles discussing complex restorative dental challenges, collecting notable works on the subject. * Presents a curated list of the best peer-reviewed articles on complex restorations from the pages of Journal of Prosthodontics * Covers management of maxillofacial defects using CAD/CAM technology, tooth wear, congenital disorders, orthodontic/prosthodontic patients, patients with surgical and maxillofacial challenges, and completely edentulous patients using new ceramic material * Offers a mix of clinical reports, research articles, and reviews

Ebooka przeczytasz w aplikacjach Legimi na:

Liczba stron: 648

Rok wydania: 2016

0,0

Oceny przyznawane są przez użytkowników Legimi, systemów bibliotecznych i innych serwisów partnerskich. Przyznawanie ocen premiowane jest punktami Klubu Mola Książkowego.

Legimi nie weryfikuje, czy opinie pochodzą od konsumentów, którzy nabyli lub czytali/słuchali daną pozycję, ale usuwa fałszywe opinie, jeśli je wykryje.