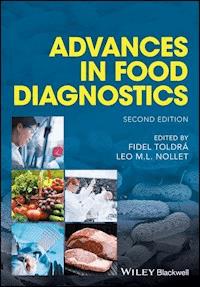

Advances in Food Diagnostics ebook

699,99 zł

Dowiedz się więcej.

- Wydawca: John Wiley & Sons

- Kategoria: Literatura popularnonaukowa

- Język: angielski

Still the most up-to-date, comprehensive, and authoritative book on food diagnostics available Featuring seven entirely new chapters, the second edition of this critically acclaimed guide has been extensively revised and updated. Once again delivering food professionals the latest advances in food diagnostics and analysis, the book approaches the topic in several different ways: reviewing novel technologies to evaluate fresh products; describing and analysing in depth specific modern diagnostics; providing analyses of data processing; and discussing global marketing, with insights into future trends. Written by an international team of experts, this volume not only covers most conventional lab-based analytical methods, but also focuses on leading-edge technologies which are being or are about to be introduced. Advances in Food Diagnostics, Second Edition: * Covers ultrasound, RMN, chromatography, electronic noses, immunology, GMO detection and microbiological and molecular methodologies for rapid detection of pathogens * Explores the principles and applications of immunodiagnostics in food safety and the use of molecular biology to detect and characterize foodborne pathogens * Includes DNA-based and protein-based technologies to detect and identify genetically-modified food or food components * Focuses on the translation of diagnostics tests from bench to the market in order to illustrate the benefits to the food industry * Provides an overview of the business end of food diagnostics; identifying the markets, delineating the sellers and the buyers, comparing current technology with traditional methods, certifying operations and procedures, and analysing diagnostic devices within the food and related industries This is an indispensable resource for food scientists, food quality analysts, food microbiologists and food safety professionals. It also belongs on the reference shelves of labs conducting food diagnostics for the analysis of the sensory, quality and safety aspects of food.

Ebooka przeczytasz w aplikacjach Legimi na:

Liczba stron: 1112

Rok wydania: 2017