569,99 zł

Dowiedz się więcej.

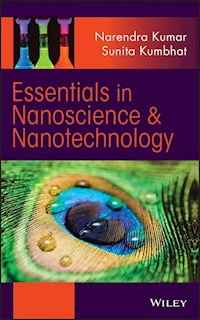

- Wydawca: John Wiley & Sons

- Kategoria: Literatura popularnonaukowa

- Język: angielski

This book describes various aspects of nanoscience and nanotechnology. It begins with an introduction to nanoscience and nanotechnology and includes a historical prospective, nanotechnology working in nature, man -made nanomaterial and impact of nanotechnology illustrated with examples. It goes on to describes general synthetic approaches and strategies and also deals with the characterization of nanomaterial using modern tools and techniques to give basic understanding to those interested in learning this emerging area. It then deals with different kinds of nanomaterial such as inorganics, carbon based-, nanocomposites and self-assembled/supramolecular nano structures in terms of their varieties, synthesis, properties etc. In addition, it contains chapters devoted to unique properties with mathematical treatment wherever applicable and the novel applications dealing with information technology, pollution control (environment, water), energy, nanomedicine, healthcare, consumer goods etc.

Ebooka przeczytasz w aplikacjach Legimi na:

Liczba stron: 945

Rok wydania: 2016