599,99 zł

599,99 zł

-50%

Zbieraj punkty w Klubie Mola Książkowego i kupuj ebooki, audiobooki oraz książki papierowe do 50% taniej.

Dowiedz się więcej.

Dowiedz się więcej.

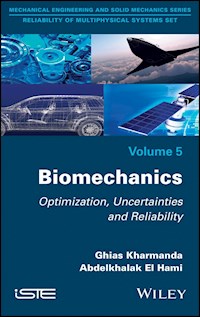

- Wydawca: John Wiley & Sons

- Kategoria: Biznes, rozwój, prawo

- Język: angielski

In this book, the authors present in detail several recent methodologies and algorithms that they developed during the last fifteen years. The deterministic methods account for uncertainties through empirical safety factors, which implies that the actual uncertainties in materials, geometry and loading are not truly considered. This problem becomes much more complicated when considering biomechanical applications where a number of uncertainties are encountered in the design of prosthesis systems. This book implements improved numerical strategies and algorithms that can be applied to biomechanical studies.

Ebooka przeczytasz w aplikacjach Legimi na:

Liczba stron: 276

Rok wydania: 2017

0,0

Oceny przyznawane są przez użytkowników Legimi, systemów bibliotecznych i innych serwisów partnerskich. Przyznawanie ocen premiowane jest punktami Klubu Mola Książkowego.

Legimi nie weryfikuje, czy opinie pochodzą od konsumentów, którzy nabyli lub czytali/słuchali daną pozycję, ale usuwa fałszywe opinie, jeśli je wykryje.